Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

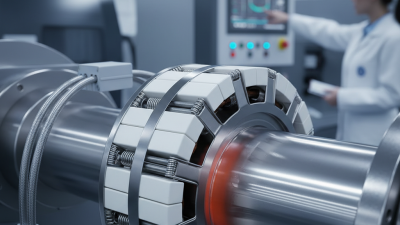

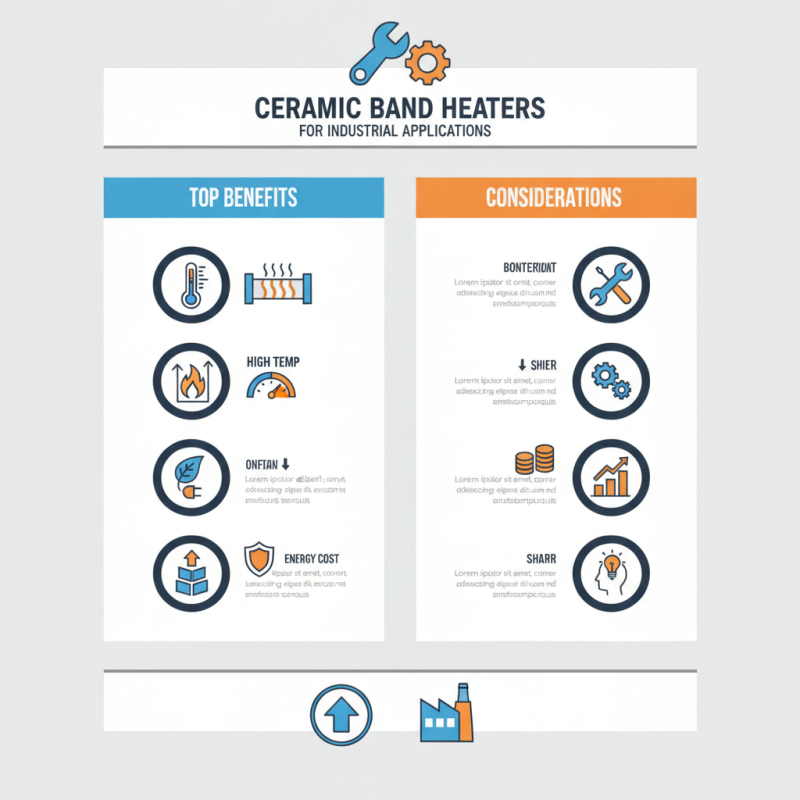

In the realm of industrial heating, the choice of equipment plays a crucial role in efficiency and effectiveness. Ceramic Band Heaters stand out for their unique benefits. These heaters are designed to provide uniform heat distribution, ensuring even temperature maintenance. This is vital for processes like extrusion or molding, where precision is key.

Their ability to withstand high temperatures makes them suitable for various applications. Moreover, Ceramic Band Heaters are energy-efficient, often reducing operational costs. Users appreciate their durable nature, which lowers the frequency of replacements. However, one must consider installation challenges and initial costs. It is important to evaluate whether the long-term benefits outweigh these factors.

These heaters can enhance productivity significantly but are not without shortcomings. Some users report difficulties in maintenance. Additionally, the familiarity with this technology can vary among operators. Embracing Ceramic Band Heaters requires a commitment to understanding their functionality fully. Nevertheless, the potential advantages often lead to greater success in industrial applications.

Ceramic band heaters offer several key advantages in industrial applications. They provide efficient and uniform heat distribution, aligning perfectly with the needs of various manufacturing processes. These heaters minimize hotspots, which can lead to product defects. The ability to maintain stable temperatures makes them ideal for producing high-quality outputs.

In addition to thermal efficiency, ceramic band heaters boast durability. Their solid construction withstands challenging environments and constant use. This resistance to wear and tear translates to lower replacement costs over time. An intriguing aspect to consider is that, despite their advantages, improper installation can lead to ineffective heating. Monitoring the heater's performance regularly is essential for optimal results.

Another benefit lies in energy savings. Ceramic band heaters consume less power compared to other heating elements. This efficiency can significantly lower operational costs. However, achieving these savings requires precision in application and maintenance practices. It’s crucial to reflect on how user habits can impact overall performance. Investing in training for staff could enhance the effectiveness of these heaters.

Ceramic band heaters have gained attention for their enhanced energy efficiency in industrial applications. With a temperature stability of ±2 Celsius degrees, they provide precise heating. This accuracy can significantly reduce energy consumption. According to a study by the Department of Energy, optimizing heating elements can save industries up to 30% in energy costs annually.

The design of ceramic band heaters contributes to their efficiency. They are lightweight and feature a fast heat-up time. This means they require less energy to reach operational temperatures. In fact, studies reveal that ceramic heaters can heat up 20% faster than traditional metal heaters. However, it’s essential to monitor their performance regularly. Inconsistent heating or uneven placement may lead to energy wastage.

Moreover, these heaters have a longer lifespan, reducing the need for frequent replacements. This longevity not only lowers operational costs but also cuts down on waste. However, issues can arise if proper maintenance is overlooked. If installations are not checked periodically, the potential energy savings could diminish over time. Industries must consider both initial costs and long-term benefits for an effective transition.

Ceramic band heaters are known for their exceptional durability. Unlike traditional heaters, they can withstand high temperatures without degradation. Industry reports show that ceramic band heaters can operate at temperatures exceeding 1,000°F (538°C). This high resistance to heat prolongs their lifespan and reliability in demanding environments.

The materials used in ceramic heaters contribute significantly to their longevity. They are made from a strong ceramic composite. This design minimizes thermal cycling stress. Studies indicate that proper maintenance and installation methods can further enhance their lifespan, allowing them to last up to 25% longer than conventional heating solutions.

In practice, longer-lasting heaters translate to reduced downtime. This can lead to significant cost savings in industrial operations. However, some users occasionally overlook proper installation techniques. This oversight can negate the benefits of durability. The need for consistent maintenance should also not be underestimated. Even with a robust design, neglect can reduce efficiency and lifespans. Adopting stricter maintenance schedules could mitigate these risks.

| Benefit | Description | Expected Longevity (Years) |

|---|---|---|

| Durability | Resistant to harsh industrial environments, ensuring long-lasting performance. | 10-15 |

| Energy Efficiency | Heats up quickly, reducing energy consumption and costs. | N/A |

| Uniform Heat Distribution | Provides consistent heating across the surface, improving product quality. | N/A |

| Low Maintenance | Requires minimal upkeep, reducing downtime and operational costs. | N/A |

| Temperature Control | Allows precise temperature management, enhancing process reliability. | N/A |

| Safe Operation | Designed with safety features to minimize risks in industrial settings. | N/A |

| High Temperature Capability | Can handle high temperatures, suitable for a variety of applications. | Up to 800°F (427°C) |

| Versatility | Applicable to a wide range of industrial processes and machinery. | N/A |

| Cost-Effective | Offers a good balance between performance and price, reducing overall costs. | N/A |

| Environmental Benefits | Lower greenhouse gas emissions due to efficient energy use. | N/A |

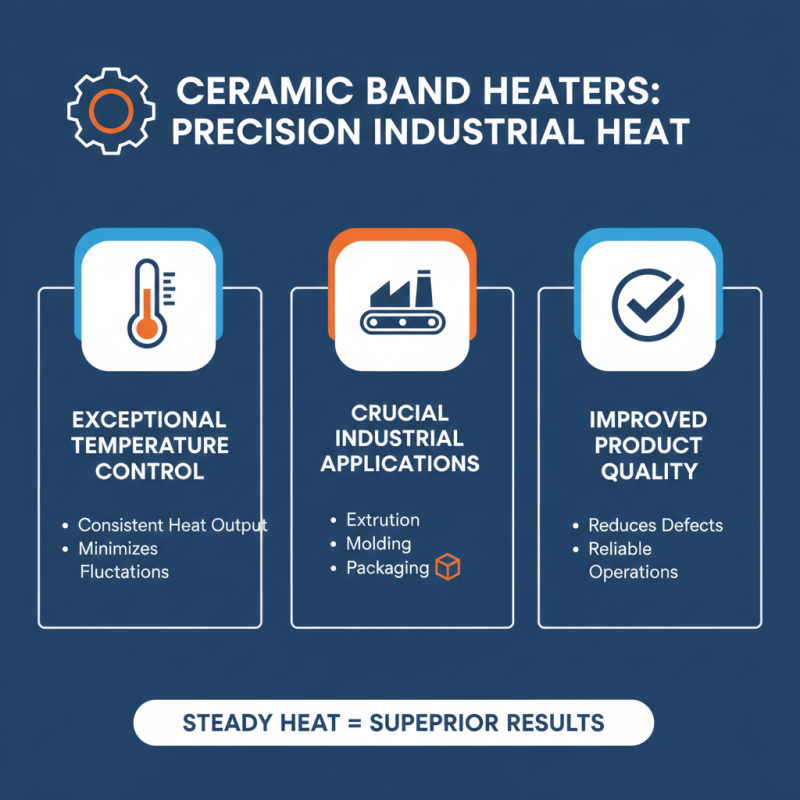

Ceramic band heaters provide exceptional temperature control in industrial applications. These heaters maintain a consistent heat output, crucial in processes like extrusion and molding. Operators rely on steady temperatures to ensure product quality. Inconsistent heating can lead to defects. This is where ceramic band heaters shine, minimizing temperature fluctuations.

Another key feature is the even heat distribution. The ceramic material ensures uniform heating across the surface. This prevents hot spots, which can damage delicate components. Operators often report fewer failures and less downtime with these heaters. However, it’s essential to monitor the surface contact closely. Sometimes, inadequate fitting can lead to uneven heating despite the heater's quality.

In real-world applications, the durability of ceramic band heaters stands out. They resist wear and tear, lasting significantly longer under stress. Yet, some users may face initial installation challenges. Proper alignment is vital for optimal performance. The learning curve can be steep, but the payoff is substantial. Repeated adjustments may be necessary until the perfect fit is achieved.

Ceramic band heaters are increasingly popular in various industrial applications. Their versatility makes them suitable for processes requiring precise temperature control. In the plastics industry, for example, these heaters can achieve temperatures up to 1,200°F. This capability is essential for maintaining the quality of materials during processing.

Many manufacturers report improved efficiency with ceramic band heaters. A study indicated that these heaters can reduce energy consumption by up to 20%. This reduction is significant, especially in facilities that operate continuously. However, achieving optimal performance requires careful installation and regular maintenance. Improper use can lead to uneven heating.

The chemical industry also benefits from ceramic band heaters. They are resistant to chemicals and can withstand harsh environments. This durability ensures longevity, yet some users overlook the importance of regular inspections. Ignoring wear and tear can lead to unexpected failures, impacting productivity. Thus, while these heaters provide numerous advantages, manufacturers must prioritize best practices to fully realize their potential.