Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

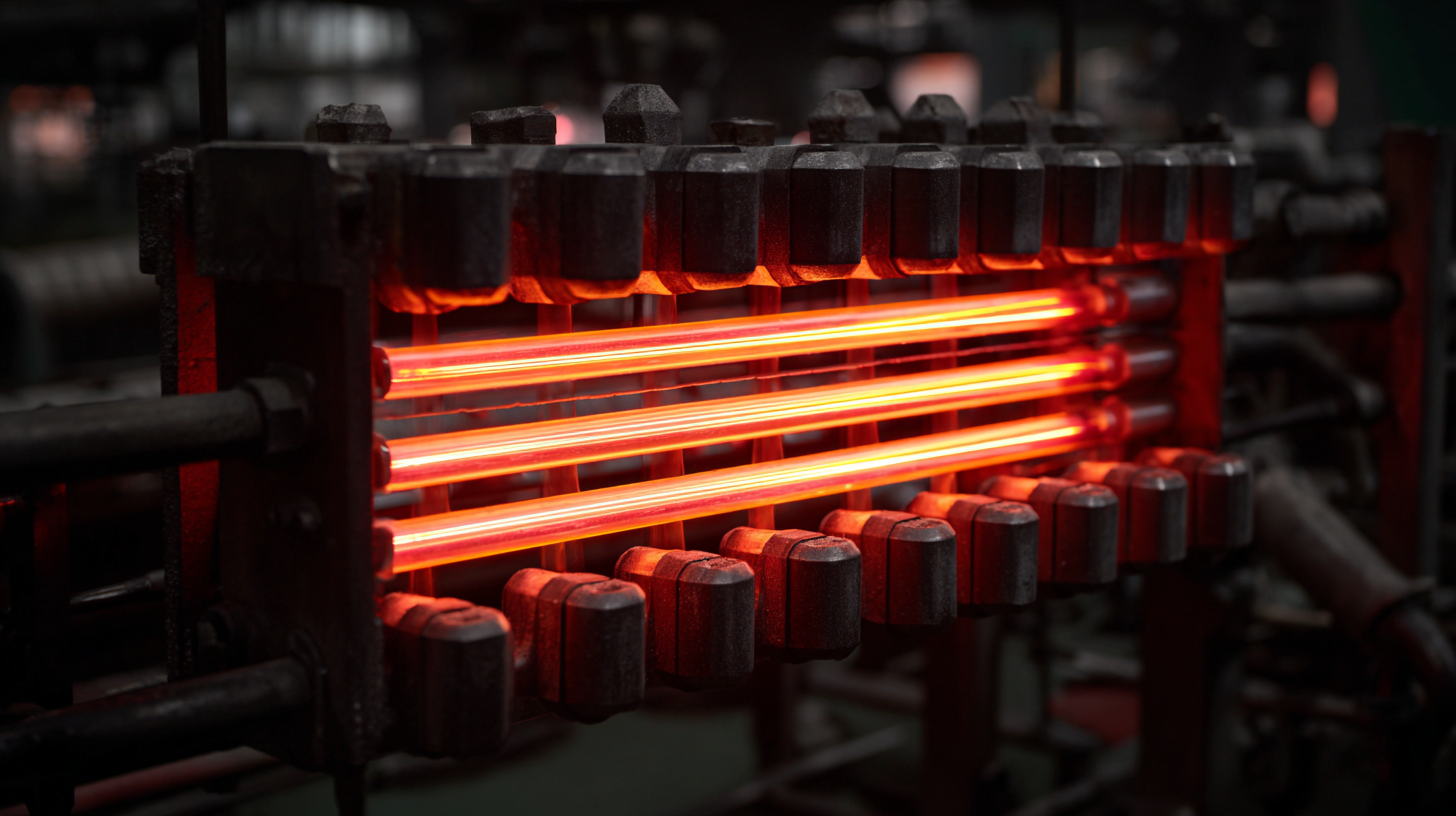

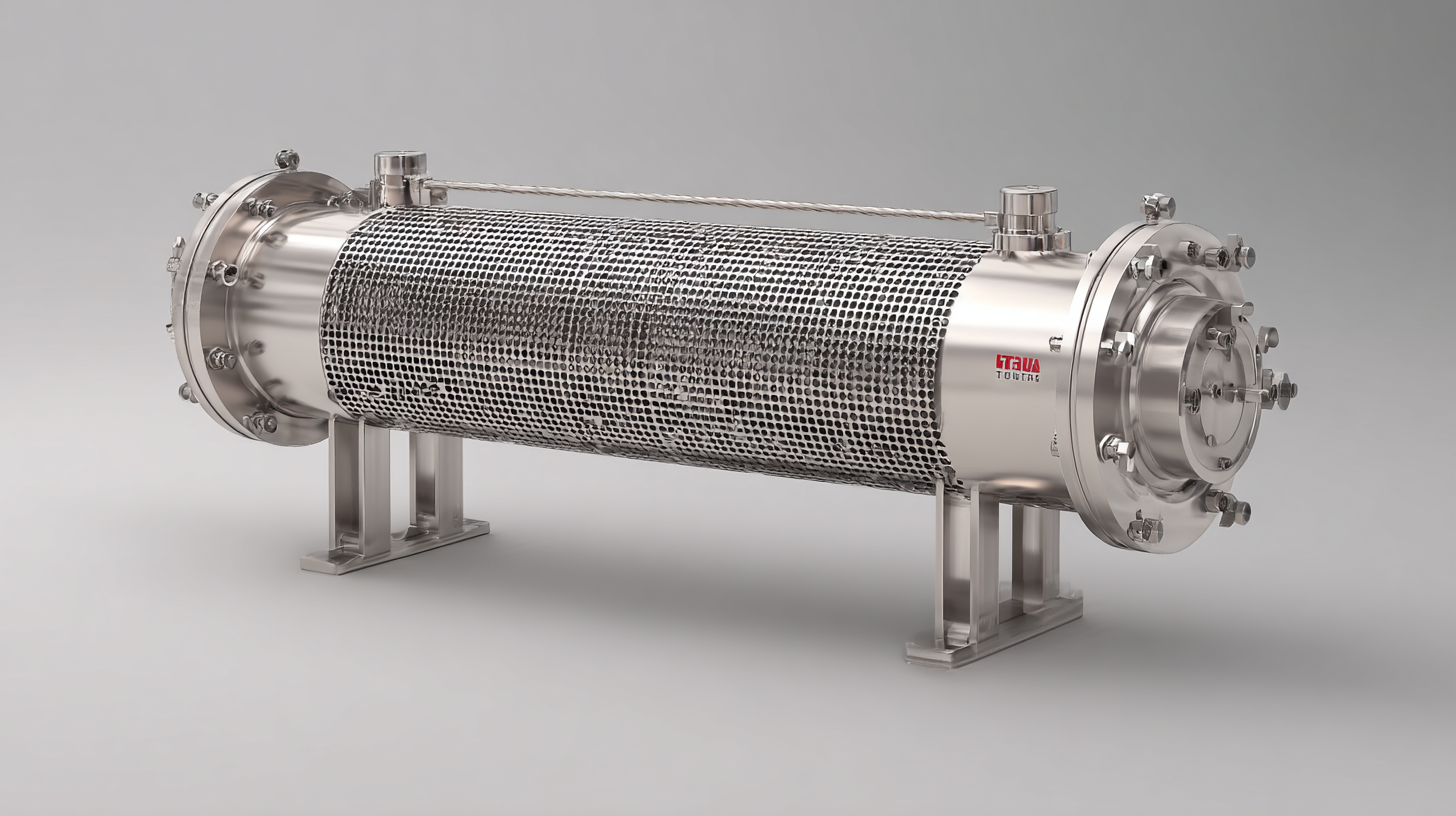

In the ever-evolving world of heating solutions, the demand for efficiency and effectiveness is paramount. The

Cast Nozzle Heater stands out as a pivotal innovation, designed to meet the rigorous needs of various industries.

According to Dr. Emily Parker, a renowned expert in thermal technology, "Cast Nozzle Heaters are not just a component; they represent a significant leap forward in the way we approach consistent heating in manufacturing processes."

This assertion highlights the crucial role these heaters play in enhancing operational efficiency.

The advantages of utilizing Cast Nozzle Heaters extend beyond mere functionality; they offer substantial benefits like

reduced energy consumption, improved heating response times, and the ability to maintain precise

temperature control. As industries strive for sustainable practices, the efficient performance of Cast Nozzle Heaters makes them an attractive option for manufacturers

looking to optimize their production lines while minimizing environmental impact. By delving into the

top ten benefits of these advanced heating solutions, organizations can better understand how to leverage this technology for enhanced productivity

and cost savings.

In the modern manufacturing landscape, cast nozzle heaters have emerged as a crucial component for enhancing efficiency and productivity. These heaters provide precise temperature control, which is essential in processes such as aluminum casting. According to a recent industry report, effective temperature regulation in manufacturing can reduce energy consumption by up to 30%, leading to significant cost savings and a lower carbon footprint. This is especially important as manufacturers face increasing pressure to adopt more sustainable practices.

The adaptability of cast nozzle heaters is another significant advantage in diverse manufacturing applications. Their design allows for easy integration into existing systems, which minimizes downtime during upgrades. The Aluminum Industry Conference highlighted that manufacturers implementing these heaters reported improvements in melt quality and cycle times, with some operations achieving a 15% increase in output. This not only enhances efficiency but also meets the growing demands for higher production rates and quality standards in aluminum casting. As industries continue to evolve, the role of efficient heating solutions like cast nozzle heaters will become even more pivotal.

Cast nozzle heaters offer remarkable improvements in energy efficiency, making them a preferred choice for various applications. Unlike traditional heating elements that consume more energy and often lead to heat loss, cast nozzle heaters are designed to minimize waste. Their robust construction allows for even heat distribution, which enables faster and more efficient heating processes. This results in reduced energy consumption, ultimately leading to lower operational costs and a smaller carbon footprint.

Furthermore, these heaters are tailored for specific industrial needs, further enhancing their effectiveness. The precision engineering of cast nozzle heaters ensures that the desired temperature is maintained with minimal energy fluctuation. This efficiency not only increases productivity but also extends the life of the equipment, reducing the frequency of replacements. As industries continue to seek sustainable and cost-effective solutions, the energy-saving benefits of cast nozzle heaters stand out, promoting a more environmentally friendly approach to heating solutions.

This chart illustrates the top 10 benefits of using cast nozzle heaters, highlighting their impact on energy efficiency, cost savings, and performance improvements.

Cast nozzle heaters are increasingly becoming the go-to solution for industries requiring precise temperature control. One of the standout benefits of these heaters is their ability to deliver consistent and uniform heating across different applications. This precision is particularly crucial in sectors like plastic injection molding and metal casting, where even minor fluctuations in temperature can lead to defects and significant economic losses. By maintaining stable temperatures, cast nozzle heaters can enhance product quality and efficiency, resulting in reduced waste and higher overall productivity.

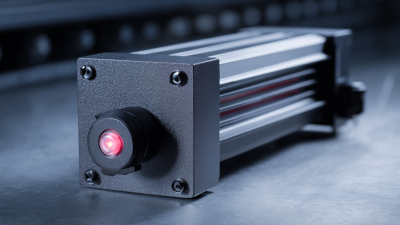

In addition to uniform heating, cast nozzle heaters are designed with advanced temperature regulation systems that allow for real-time monitoring and adjustment. This capability is essential for precision applications where temperature variations can affect material properties and part dimensions. With enhanced control mechanisms, operators can fine-tune heating processes to match specific production needs, thus optimizing their operations. This leads not only to better quality control but also to energy savings, as the heaters can operate more efficiently than traditional heating methods, minimizing power consumption without compromising performance.

| Benefit | Description | Impact on Applications |

|---|---|---|

| Improved Temperature Control | Allows precise heating for delicate processes. | Enhances product quality and consistency. |

| Energy Efficiency | Reduces energy consumption compared to traditional heaters. | Lower operational costs and carbon footprint. |

| Rapid Heating | Reaches desired temperatures quickly. | Increases production speed and efficiency. |

| Compact Design | Space-saving, ideal for limited workspaces. | Enhances flexibility in equipment layout. |

| Long Lifespan | Durable construction leads to fewer replacements. | Reduces maintenance downtime and costs. |

| Versatility | Suitable for various applications across industries. | Maximizes utility in multiple production environments. |

| Minimal Heat Loss | Designed to retain heat efficiently. | Improves overall heating effectiveness. |

| Safety Features | Includes safety measures to prevent overheating. | Enhances worker safety and compliance. |

| Simplified Installation | Easy to integrate into existing systems. | Reduces installation time and labor costs. |

| Cost-Effective Solutions | Offers high performance at competitive pricing. | Significant return on investment for manufacturers. |

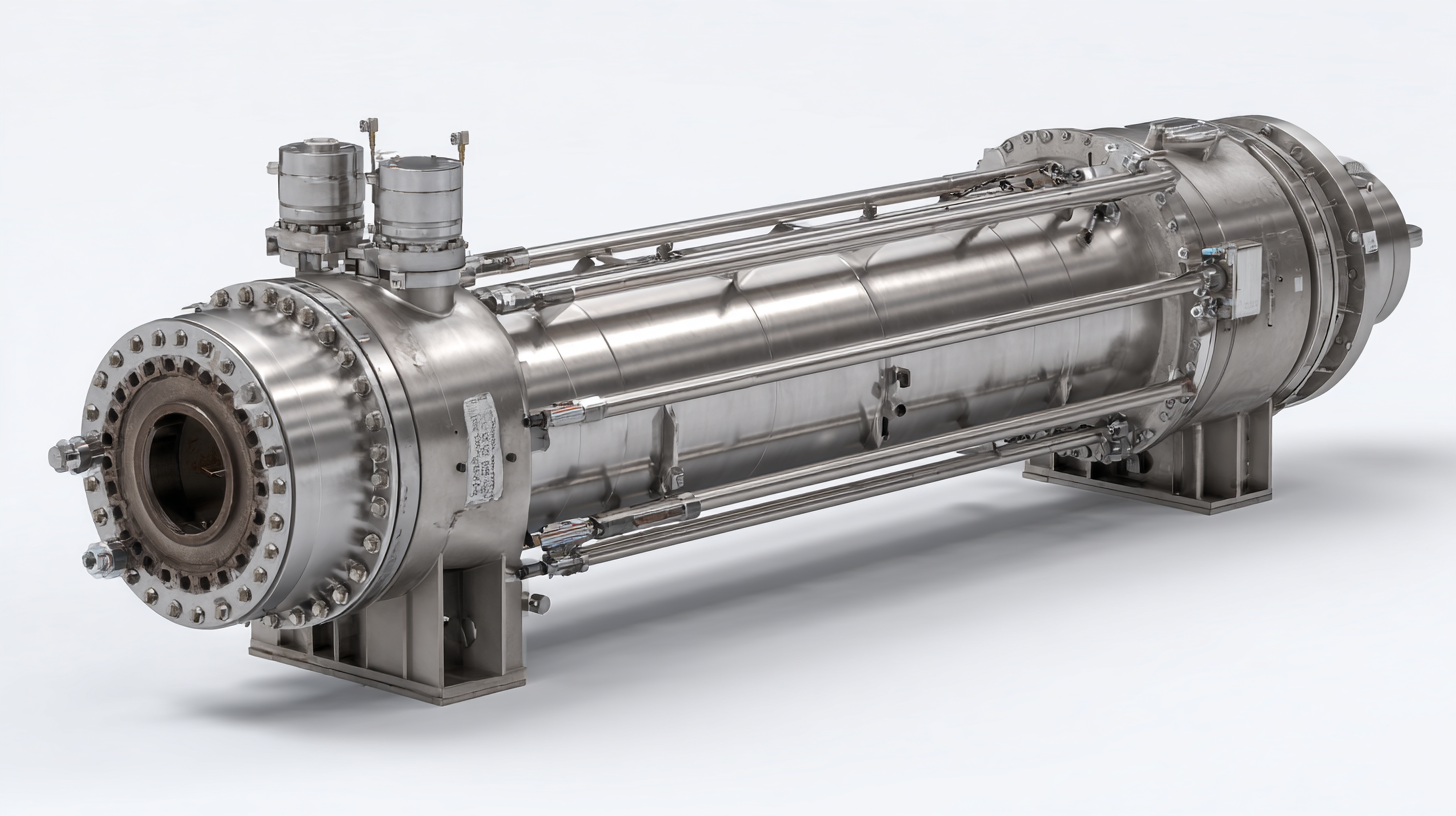

Cast nozzle heaters are becoming increasingly popular in various industrial applications due to their remarkable durability and longevity. These heaters are designed to withstand high temperatures and pressures, making them ideal for environments where traditional heating solutions may fail. The robust construction of cast nozzle heaters not only enhances their operational lifespan but also reduces the frequency of replacements, resulting in significant cost savings over time.

When selecting cast nozzle heaters, it's essential to consider materials and design specifications that enhance durability. Look for heaters made from high-quality alloys and those that feature insulation to reduce heat loss. Additionally, regular maintenance can dramatically extend the lifespan of these heating solutions.

Tip: Always monitor the temperature and usage patterns of your heaters. Implementing a routine check-up schedule will help catch any potential issues early, ensuring that your heating solutions remain efficient and long-lasting. Another tip is to invest in professional installation; proper setup can vastly improve the performance and longevity of cast nozzle heaters. Adopting these practices will ensure that your investment in heating technology pays off for years to come.

Cast nozzle heaters have become a preferred choice in various industrial settings due to their remarkable cost-effectiveness and efficient heating capabilities. These heaters are designed to deliver rapid and uniform heat transfer, making them ideal for applications where precision and reliability are crucial.

By utilizing cast nozzle heaters, companies can achieve significant reductions in energy consumption, thereby lowering operational costs. The ability to maintain consistent temperatures not only enhances productivity but also minimizes material waste, further contributing to financial savings.

Moreover, the cast material used in these heaters offers durability and longevity, which translates to reduced maintenance expenses over time. Industries that rely on heating solutions, such as plastics manufacturing or food processing, can particularly benefit from this advantage, as the enhanced lifespan of equipment ensures continuity in production processes.

As the hydronic radiators market continues to grow, driven by increasing demand for efficient temperature control systems, the implementation of cost-effective heating solutions like cast nozzle heaters will play a vital role in shaping the industry’s future.