Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the competitive landscape of manufacturing and production, choosing the right tools and machinery can significantly impact operational efficiency and bottom line. Industrial Infrared Heaters, known for their quick heating capabilities and energy efficiency, are becoming an indispensable choice for many businesses. As industry expert Dr. Emily Thompson states, “The right application of infrared heating technology can not only enhance productivity but also reduce energy costs significantly.”

When considering Industrial Infrared Heaters for your business needs, it is crucial to understand the diverse range of options available, as well as the specific requirements of your operations. Factors such as heater type, power consumption, and intended use can all influence the effectiveness and ROI of the heating solution.

In this guide, we will explore key considerations for selecting the best Industrial Infrared Heaters, ensuring that your investment aligns perfectly with your operational goals and enhances your overall efficiency. With insights from industry professionals and practical tips, you'll be empowered to make informed decisions that will ultimately drive your business towards success.

When selecting industrial infrared heaters for your business, it's crucial to consider several key factors that align with your operational needs. First, evaluate the specific heating requirements of your facility. Different environments may require varying heating intensities, and understanding the area you need to heat will guide you in choosing the appropriate heater type.

Tips: Always measure the size of the area you intend to heat and choose heaters with adequate output to ensure efficiency and effectiveness. Additionally, consider the type of infrared heater: short-wave heaters offer quick heating, while medium to long-wave options provide more uniform heat distribution.

Another important aspect is the energy efficiency of the heaters. Look for models that boast high energy ratings, as these will not only reduce your utility bills but also minimize your carbon footprint.

Tips: Investing in energy-efficient options can lead to significant savings in the long run. Research the latest technologies, such as smart heaters, that can adapt to varying operational schedules, ensuring optimal performance and energy consumption.

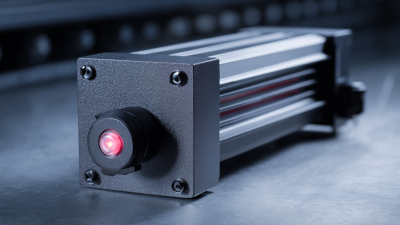

When selecting the best industrial infrared heaters, it's essential to understand the different types available and their specific applications. There are three main categories of infrared heaters: short-wave, medium-wave, and long-wave. Short-wave heaters emit high-intensity infrared radiation that provides rapid heating and is ideal for applications requiring quick turnaround times, such as curing coatings or drying paint. These heaters are typically used in situations where precise temperature control is critical.

Conversely, medium-wave heaters are more versatile and are often used in processes that require a balance between quick heating and energy efficiency, such as in textile and metal drying. Long-wave infrared heaters are particularly useful for heating larger areas and providing consistent warmth over extended periods. They work by warming the surrounding air and surfaces, making them suitable for applications like space heating in warehouses or factories. Understanding these distinctions will help businesses choose the right type of infrared heater to meet their specific operational requirements.

When selecting industrial infrared heaters, evaluating their energy efficiency and cost-effectiveness is crucial to maximize return on investment. According to the U.S. Department of Energy, infrared heaters can achieve energy efficiencies of up to 90%, significantly higher than conventional heating systems that typically operate at around 60-70% efficiency. This remarkable efficiency translates into reduced energy consumption, which is essential for businesses looking to lower operational costs while meeting stringent environmental regulations.

Cost-effectiveness also hinges on the long-term operational savings that stem from these heaters. For instance, a recent industry report by the International Energy Agency (IEA) highlighted that infrared heating systems can reduce energy costs by up to 50% compared to traditional heating methods. Additionally, their ability to heat objects directly rather than the surrounding air leads to faster warm-up times and less energy wasted, making them an attractive option for factories and warehouses with high ceilings or open layouts. These factors not only contribute to a greener business model but also reflect positively on the bottom line, validating the decision to invest in infrared heating technology.

When selecting industrial infrared heaters, understanding the heating capacity and coverage is crucial for aligning the equipment with specific business applications. According to a report by the U.S. Department of Energy, infrared heaters can improve energy efficiency by up to 50% in comparison to traditional heating methods. This efficiency is largely attributed to their ability to directly heat objects and surfaces rather than the air, making them an ideal choice for manufacturing settings where warm-up time and energy consumption must be minimized.

Moreover, assessing the coverage area of infrared heaters is vital for optimizing their performance. Studies indicate that a typical infrared heater can effectively cover an area ranging from 100 to 1,200 square feet, depending on the heater type and power output. For heavy-duty applications, such as in warehouses or processing plants, selecting heaters with higher wattage may be necessary to ensure uniform heat distribution. It is also important to consider the height at which the heaters will be installed; for instance, overhead mounted heaters may require adjustments in output to avoid hot spots and ensure consistent coverage throughout the workspace. By evaluating these parameters, businesses can achieve enhanced productivity and reduced operational costs.

When selecting the best industrial infrared heaters for your business needs, certain key features should be prioritized to ensure efficiency and effectiveness. One of the most crucial factors is the heating efficiency, which indicates how well the heater converts energy into heat. Look for models with high energy conversion rates, as they will not only save on operational costs but also provide faster heating in larger spaces.

Another essential feature to consider is the heater's construction and durability. Industrial environments can be demanding, so opting for heaters built with high-quality materials that withstand harsh conditions is important. Additionally, check for safety features like overheat protection and automatic shut-off mechanisms, which enhance workplace safety. Finally, the ability to easily adjust temperature settings can be a significant advantage, allowing for more precise control over the heating process and enhancing productivity, especially as the outdoor electric heating market is set to grow significantly in the coming years.

| Feature | Description | Importance |

|---|---|---|

| Heating Element Type | Types include ceramic, quartz, and carbon fiber, each with different heat transfer rates. | High |

| Power Consumption | Measured in watts; higher wattage typically means faster heating. | Medium |

| Temperature Range | The ability to maintain varying temperatures based on process needs. | High |

| Durability | Resistance to wear and tear, especially in industrial settings. | High |

| Safety Features | Includes overheat protection, automatic shut-off, etc. | High |

| Portability | Weight and ease of movement can affect installation and usage. | Medium |