Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

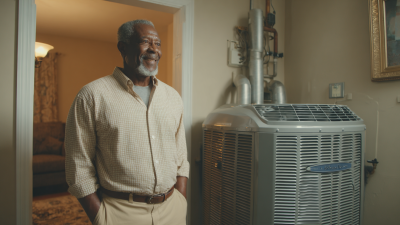

In the pursuit of optimal thermal management, the Duraband Nozzle Band Heater emerges as a pivotal solution, enabling manufacturers to enhance their operational efficiency significantly. According to a recent report from the International Journal of Thermal Sciences, improper thermal control in manufacturing processes can lead to energy losses of up to 30%, adversely affecting productivity and costs. The Duraband Nozzle Band Heater is designed to optimize temperature distribution and minimize heat loss, ensuring that thermoplastics are processed at ideal conditions. This advanced heater guarantees uniform heating, which not only improves product quality but also extends the lifespan of equipment. With the global market for heating equipment projected to reach $61 billion by 2027, investing in high-performance solutions like the Duraband Nozzle Band Heater is not only beneficial but essential for staying competitive in the manufacturing landscape.

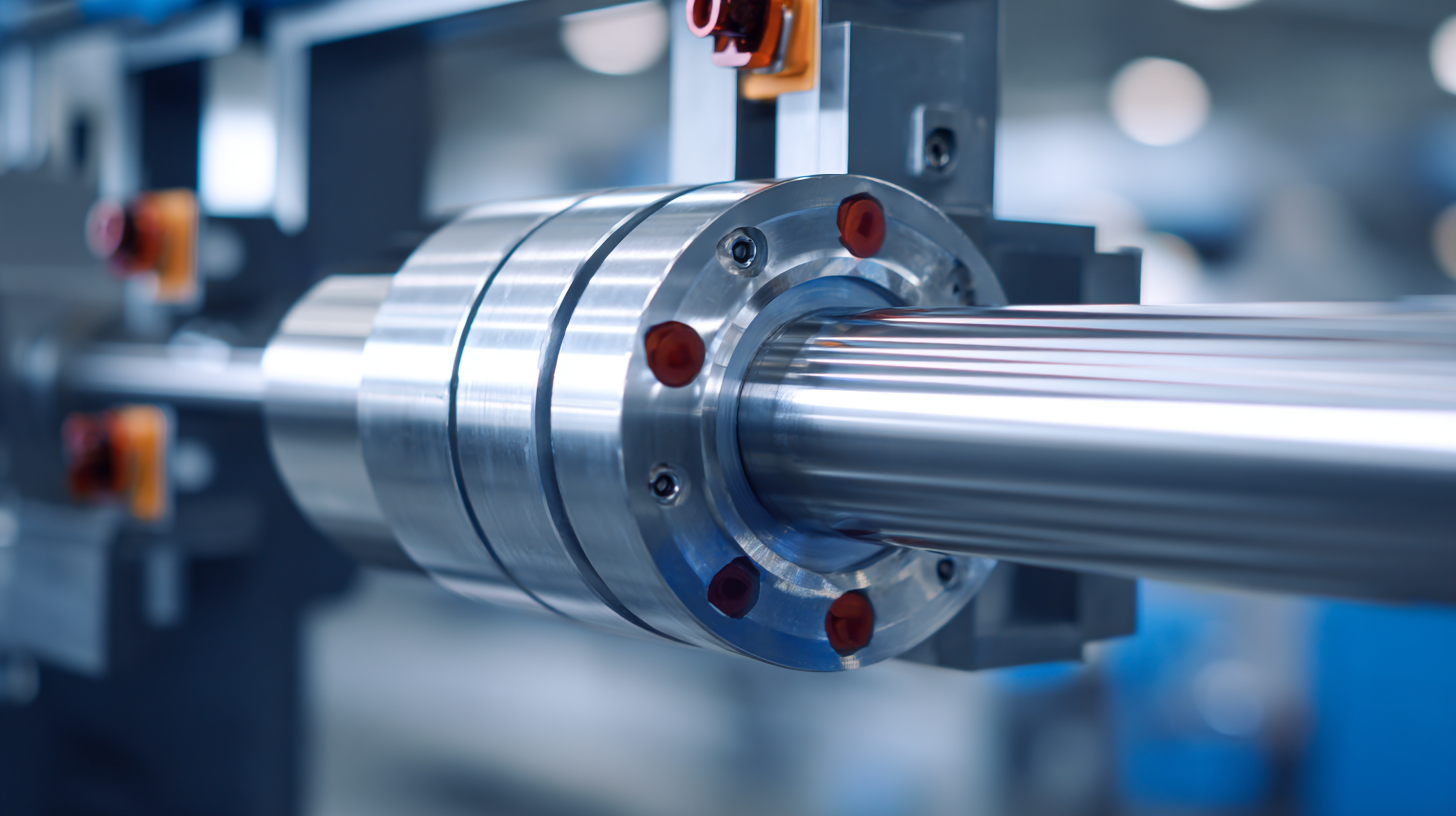

When selecting the right Duraband Nozzle Band Heater for your application, it's essential to consider several key factors that directly impact efficiency and performance. One of the most critical aspects is the heater's size—ensuring that it fits snugly around the nozzle will enhance heat distribution and minimize energy loss. Additionally, the watt density of the heater is another crucial parameter; higher watt densities may be suitable for applications requiring rapid heat-up times, while lower densities are ideal for sustained heat applications.

Tips: Always assess the specific material of your nozzle as different materials have varying thermal conductivity, which can influence the choice of heater. For example, a stainless steel nozzle may require a different band heater specification compared to a brass one.

Another important consideration is the operating environment. Factors like temperature range, humidity, and potential exposure to corrosive materials will dictate the durability and longevity of your heater. Opting for a model with good insulation and resistance to the application’s specific conditions will not only protect your investment but also optimize thermal management in the long run.

Tips: Evaluate your application's energy efficiency requirements. Choosing a model that aligns with your energy usage goals can lead to significant savings and reduced environmental impact over time.

Installing a Duraband Nozzle Band Heater is essential for achieving optimal thermal management in various applications. This step-by-step guide aims to break down the installation process into manageable tasks, ensuring that even those new to thermal solutions can effectively implement this technology. Start by gathering all necessary tools and materials, which typically include the heater, an appropriate power supply, and mounting hardware.

Begin the installation by carefully reading the manufacturer’s instructions and safety guidelines. Make sure to clean the surface of the nozzle thoroughly to ensure a secure fit. Next, align the heater around the nozzle, making sure it’s snug but not overly tight, as this could damage both the heater and the nozzle. Once everything is properly positioned, fasten the heater in place and connect it to the power supply, following all electrical safety precautions.

**Tips:** Always verify that the power is turned off before starting any electrical work to prevent accidents. Additionally, inspecting the heater regularly for wear and tear can enhance its longevity and efficiency. Lastly, consider integrating thermal insulation to further boost heating efficiency, especially in colder environments.

In today's fast-paced manufacturing environment, maintaining precise temperature control is critical for efficiency and productivity. The Duraband Nozzle Band Heater stands at the forefront of thermal management solutions, utilizing advanced Duraband technology to optimize temperature regulation. By enveloping nozzle areas with uniform heat distribution, it minimizes thermal fluctuations, thereby enhancing overall process stability. This innovation ensures that materials remain at the ideal temperature for processing, reducing energy consumption and improving product quality.

**Tips:** To maximize the effectiveness of Duraband technology, ensure that the heater is properly calibrated to your specific application requirements. Regular maintenance and checks on the heater's integration can prevent potential downtimes caused by thermal inconsistencies. Additionally, consider the insulation surrounding the heater to further enhance heat retention and control.

With Duraband’s strategic design, operators can achieve a more reliable performance, less wear on equipment, and a decrease in production costs. By focusing on efficient thermal management, businesses can ultimately enhance their operational capabilities and stay competitive in their respective markets.

This chart illustrates the temperature variations during different phases of thermal management using Duraband Nozzle Band Heater technology. It highlights the efficiency achieved at optimal stages, showcasing maximum stabilization in temperature control.

Proper maintenance of your Duraband nozzle band heater is essential for ensuring optimal thermal management and longevity. According to a report from the Plastics Industry Association, properly maintained heating equipment can improve energy efficiency by up to 30%. One key maintenance tip is to regularly inspect the heater for any signs of wear or damage. Look for frayed wires, signs of overheating, or insulation damage, as these can significantly affect performance and lead to costly downtime.

In addition to regular inspections, it's crucial to keep the heater clean. Built-up residues can act as insulators, hindering efficient heat transfer and leading to higher energy consumption. The American Society of Mechanical Engineers suggests that routine cleaning procedures should be implemented, especially in environments with high particulate matter. Utilizing an appropriate cleaning agent and following manufacturer guidelines can greatly enhance the lifespan of your heater, ensuring it operates at peak efficiency. Adhering to these maintenance tips not only contributes to a longer operational life but also optimizes the thermodynamic performance, allowing for greater productivity and cost savings in your manufacturing processes.

| Aspect | Details |

|---|---|

| Heater Type | Nozzle Band Heater |

| Temperature Range | Up to 400°C (752°F) |

| Power Density | 10-30 W/in² |

| Material | High-Grade Silicone |

| Insulation | Highly Thermally Efficient |

| Maintenance Frequency | Monthly |

| Common Issues | Thermal Degradation, Electrical Failures |

| Warranty Period | 1 Year |

| Cleaning Method | Soft Cloth, Non-Abrasive Cleaner |

| Temperature Monitoring | Recommended |

When utilizing the Duraband nozzle band heater, efficiency in thermal management is vital, yet users may encounter common issues that can hinder performance. One prevalent problem is inconsistent heating, which can lead to uneven material flow during processing. This issue often arises due to improper installation or malfunctioning controls. Ensuring that the heater is correctly fitted and regularly checking the thermocouple and control system can mitigate these concerns.

Another common issue is thermal stress caused by overheating. This can damage not only the band heater but also the surrounding machinery. Users should monitor the temperature settings closely and implement a suitable insulation strategy to optimize heat retention while safeguarding against excessive temperature fluctuations. Regular maintenance, including inspection for wear and tear, can help identify potential problems before they escalate, ensuring the Duraband nozzle band heater operates at peak efficiency. By addressing these common troubleshooting scenarios, businesses can enhance their thermal management processes and improve overall productivity.