Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

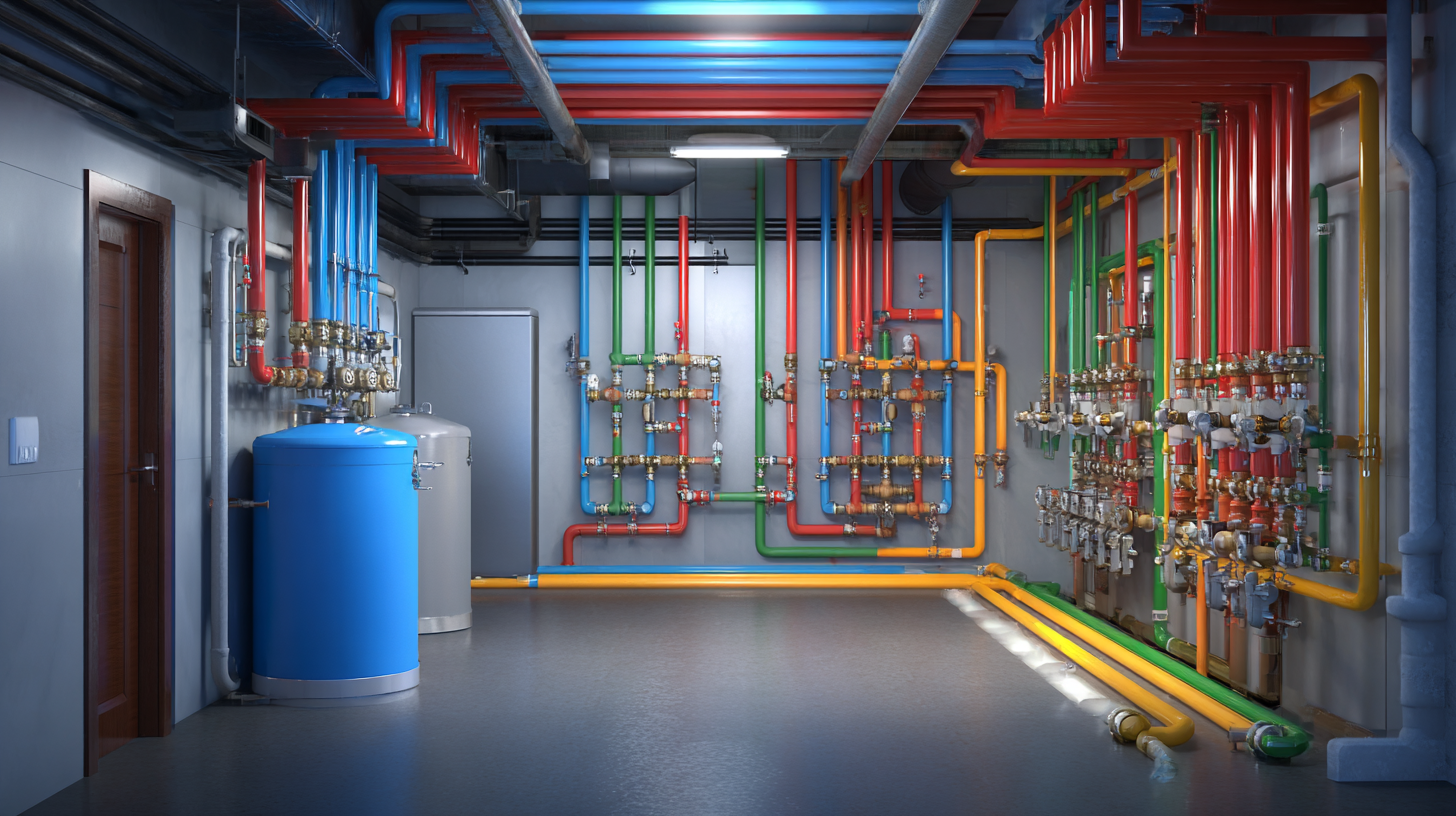

Heater pipes are integral components of modern heating systems, directly influencing thermal efficiency and overall energy savings in residential settings. According to the U.S. Department of Energy, nearly 50% of energy consumption in homes can be attributed to heating and cooling, making the optimization of heating systems crucial for energy efficiency. The performance of heater pipes, which are designed to transfer heat effectively from the heating source to the living spaces, is pivotal in this equation.

A recent industry report indicates that homes equipped with high-efficiency heater pipes can reduce energy consumption by up to 30%, resulting in significant cost savings and a lower carbon footprint. Understanding the mechanics behind heater pipes and their thermal efficiency can empower homeowners to make informed decisions, leading to improved home comfort and sustainability.

When evaluating the thermal efficiency of heater pipes, understanding the key metrics is crucial for optimizing home energy savings. Industry standards such as the U-value and the R-value serve as foundational metrics. The U-value measures the rate of heat transfer through a material; a lower U-value indicates better insulation performance, which contributes to reduced energy consumption. Conversely, the R-value reflects the material's resistance to heat flow—higher values signify superior insulating properties. Collectively, these measurements help homeowners make informed decisions when selecting heater pipes and insulation materials.

Implementing best practices in heating pipe installation can significantly enhance thermal efficiency. Proper insulation around pipes is essential to minimize heat loss, which can lead to increased energy expenditures. Additionally, ensuring that pipes are routed efficiently within the home and minimizing bends and fittings can help maintain optimal heat distribution. Regular maintenance checks can also prevent leaks and ensure that systems are functioning at peak efficiency. By adhering to these standards and practices, homeowners can effectively maximize their heater pipes' thermal efficiency, resulting in substantial energy savings and lower utility costs.

The chart above represents the thermal efficiency of different types of heater pipes. Understanding these efficiencies can aid homeowners in making informed decisions regarding energy savings and optimizing home heating systems.

Insulation plays a pivotal role in enhancing the thermal efficiency of heater pipes in residential settings. By minimizing heat loss during the transfer of hot water or air, properly insulated pipes maintain optimal temperatures more effectively. This means that homeowners can rely on their heating systems to operate efficiently, leading to reduced energy consumption and lower utility bills. In colder climates, where heating needs are more pronounced, the impact of insulation becomes even more crucial, ensuring that warmth is delivered where it is most needed without unnecessary losses.

Insulation plays a pivotal role in enhancing the thermal efficiency of heater pipes in residential settings. By minimizing heat loss during the transfer of hot water or air, properly insulated pipes maintain optimal temperatures more effectively. This means that homeowners can rely on their heating systems to operate efficiently, leading to reduced energy consumption and lower utility bills. In colder climates, where heating needs are more pronounced, the impact of insulation becomes even more crucial, ensuring that warmth is delivered where it is most needed without unnecessary losses.

Moreover, the type of insulation used can significantly affect performance. Materials such as fiberglass, foam, or reflective insulation each offer unique benefits in terms of thermal resistance and installation ease. High-quality insulation not only prevents heat loss but also protects pipes from freezing in extreme temperatures, which can lead to costly repairs. By investing in proper insulation for heater pipes, homeowners are not just enhancing energy efficiency; they are also contributing to overall home comfort and sustainability, making a significant difference in energy savings over time.

When evaluating the thermal efficiency of heater pipes, a comparative analysis between traditional and modern designs reveals significant differences in efficiency rates. Traditional heater pipes, commonly found in older homes, often utilize basic metallic materials that can lead to substantial heat loss. According to the Department of Energy, homes with standard piping configurations can experience efficiency losses of up to 30%. This inefficiency not only increases utility bills but also places a greater strain on HVAC systems, ultimately compromising the home’s energy consumption profile.

Conversely, modern heater pipe designs incorporate advanced materials and technologies that enhance thermal efficiency. For instance, insulated and reflective materials now standard in contemporary systems can significantly reduce heat loss. A report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that modern designs can improve energy efficiency ratings by as much as 50% compared to traditional systems. These advancements not only contribute to lower energy costs but also promote a more sustainable approach to home heating, aligning with the growing trend of energy-conscious living.

Optimizing heater pipe systems can significantly enhance home energy efficiency, as demonstrated in various case studies. In one instance, a mid-sized home in a temperate climate implemented a retrofitted insulating system around its heater pipes. This adjustment led to a remarkable 20% reduction in energy costs over the winter months. The insulating materials not only minimized heat loss but also allowed the heating system to reach optimal temperatures more quickly, resulting in less energy consumption overall.

Another compelling case involves a residential complex that integrated smart technology with their heater pipe systems. By installing sensors that monitored temperature fluctuations and adjusted the heating output accordingly, residents experienced a 15% decrease in their annual energy bills. This data-driven approach not only maximized efficiency but also provided valuable insights into usage patterns, enabling further optimization of energy consumption. Such examples highlight the transformative impact of optimized heater pipe systems on home energy savings, showcasing the potential for innovative solutions to create more sustainable living environments.

| Case Study | Heater Pipe Type | Thermal Efficiency (%) | Annual Energy Savings ($) | Home Size (sq ft) | Installation Cost ($) | Payback Period (Years) |

|---|---|---|---|---|---|---|

| Home A | Copper Pipes | 90 | 450 | 2000 | 2000 | 4.44 |

| Home B | Plastic Pipes | 85 | 375 | 1500 | 1500 | 4.00 |

| Home C | Steel Pipes | 88 | 425 | 1800 | 1800 | 4.24 |

| Home D | Aluminum Pipes | 92 | 500 | 2200 | 2500 | 5.00 |

| Home E | Composite Pipes | 87 | 400 | 2400 | 2200 | 5.50 |

Heater pipes play a crucial role in optimizing thermal efficiency within home heating systems. Research indicates that poorly insulated or inefficient heater pipes can contribute to up to 20% of a home's total energy consumption. A report by the U.S. Department of Energy reveals that improving the insulation around heating pipes can lead to energy savings of approximately 10-30% annually, depending on the home's design and geographic location.

Quantitative analyses show that the efficiency of heater pipes directly correlates with annual energy costs. For instance, a household that effectively insulates its heater pipes can save an average of $200 to $500 per year on energy bills. This substantial reduction comes from minimizing heat loss and improving the overall efficiency of the heating system. The Environmental Protection Agency estimates that retrofitting existing heater pipe systems could potentially reduce national energy consumption by billions of kilowatt-hours each year, significantly impacting both residential energy expenses and environmental sustainability.