Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

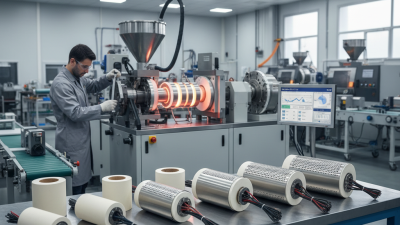

Mica Insulated Band Heaters have become essential in various industrial applications. According to a market report by Research and Markets, the global industrial heater market is expected to grow significantly, reaching $3.5 billion by 2025. Mica Insulated Band Heaters are favored for their efficiency and reliability in heating processes. They play a crucial role in the plastics, rubber, and food industries, where precise temperature control is vital.

One of the key benefits of Mica Insulated Band Heaters is their rapid heating capability. This feature minimizes downtime and increases productivity. Furthermore, they are energy-efficient, which can lead to substantial savings in operational costs. However, their effectiveness can be compromised if not installed correctly. Regular maintenance is also essential to avoid overheating issues.

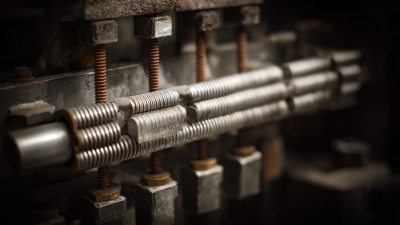

Their compact design allows easy installation on various surfaces. This flexibility makes Mica Insulated Band Heaters suitable for diverse applications. Many industries rely heavily on consistent heat distribution. Ultimately, understanding these benefits is vital for optimizing operations in any heat-sensitive application.

Mica insulated band heaters offer significant advantages for industrial heating applications. They excel in providing consistent and efficient heat, crucial for precise temperature control. These heaters are often lightweight and flexible, making installation easier in various settings. Their compact design fits snugly around different shapes, enhancing their versatility. This adaptability is beneficial in manufacturing where space is at a premium.

The durability of mica insulated band heaters is another key benefit. They withstand high temperatures and resist wear over time. This longevity results in lower replacement costs, helping businesses save money. However, some users may notice that, if not maintained, these heaters can lose efficiency. Regular checks are necessary to ensure optimal performance.

Additionally, mica heaters offer fast heating capabilities. They can reach desired temperatures quickly, increasing productivity. While it’s impressive, this feature can be a double-edged sword. If not monitored, overheating may occur, leading to potential damage. Thus, training personnel on proper usage is vital. Adopting these heaters can enhance industrial operations, but careful implementation is essential.

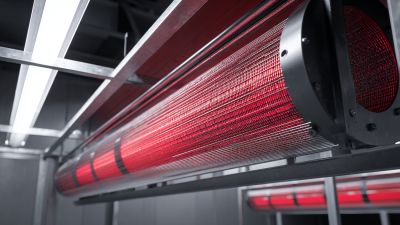

Mica insulated band heaters are known for their exceptional energy efficiency. These heaters can reach high temperatures quickly, minimizing energy consumption. With a rapid heat-up time, they allow for quicker processing cycles. This efficiency translates to reduced power usage and lower operating costs.

Using mica insulation, these band heaters effectively retain heat. This feature prevents energy loss and ensures that heat is directed precisely where needed. As a result, they not only save energy but also enhance productivity in various applications. However, it is crucial to monitor temperature closely, as overheating can occur if not managed properly.

In industrial settings, implementing mica insulated band heaters can significantly impact overall energy efficiency. They suit diverse heating requirements, from plastics to food processing. Nevertheless, users must be mindful of regular maintenance to avoid performance issues. While these heaters offer many advantages, their effectiveness relies on proper usage and care.

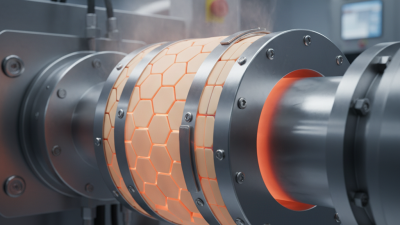

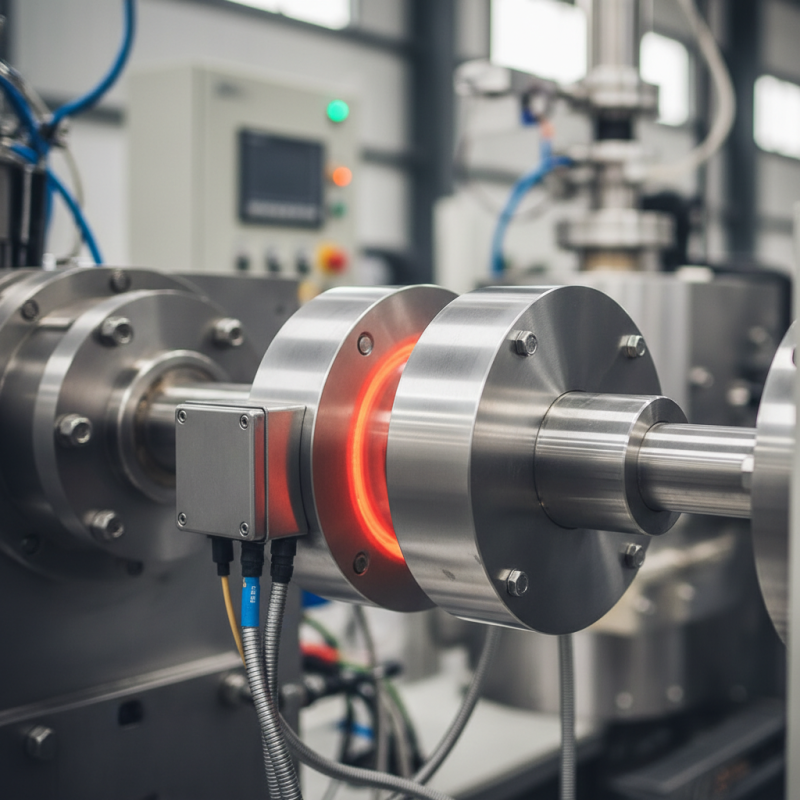

Mica insulated band heaters are known for their enhanced temperature control capabilities. These heaters provide consistent heat, which is crucial in various industrial applications. The mica insulation allows for a stable temperature profile across the heating surface. This is particularly beneficial for materials that require precise melting or heating.

When using mica insulated band heaters, the heat distribution is often more uniform than with other types. This reduces hotspots, which can damage cables or components. Many users have noticed fewer quality control issues because of this. However, achieving perfect results can be challenging. There may still be instances of uneven heating, depending on the application setup. Users should regularly monitor performance.

Moreover, responding to temperature fluctuations is vital. Mica heaters respond quickly to adjustments, which helps maintain tight temperature tolerances. It's an advantage but can also lead to overreactions if not calibrated correctly. Users sometimes struggle with finding the right balance between quick response and stability. Regularly reviewing processes might help in addressing these inconsistencies.

Mica insulated band heaters stand out for their durability in harsh environments. They can endure extreme temperatures and resist oxidation. This makes them ideal for applications in various industries. These heaters maintain consistent performance even under stress. Their design enables them to perform efficiently in critical conditions.

In demanding settings, a mica insulated band heater can last significantly longer than other heating options. However, improper installation can affect their longevity. Users must pay attention to installation techniques to avoid common pitfalls. Regular maintenance also plays a key role. Inspecting for wear and tear promotes reliable operation. While they are robust, neglecting care can lead to premature failure.

In the end, mica insulated band heaters provide reliability and performance. Their design is tailored for resilience. Still, their success relies on proper use and regular maintenance. Users must remain vigilant to maximize their benefits.

Mica insulated band heaters are gaining popularity for their cost-effectiveness in long-term operations. They are known for their excellent thermal conductivity. This allows for quick heating and efficient energy use. In many industries, energy costs can be a significant part of operational expenses. Mica heaters can minimize these costs through their efficient design.

Mica heaters offer durability, which contributes to their long-term value. They tend to have a longer lifespan compared to other types of heaters. This durability means less frequent replacements and reduced maintenance costs. However, users must be mindful of installation. Poor installation can lead to inefficiencies. It is crucial to follow guidelines for optimal performance.

Another factor to consider is the versatility of mica insulated band heaters. They can be used in various applications, from plastics to food processing. This adaptability can reduce the need for multiple heating solutions. Still, one must assess specific needs before committing to this option. Balancing upfront costs with expected longevity is vital. Failing to do so could impact overall savings.