Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

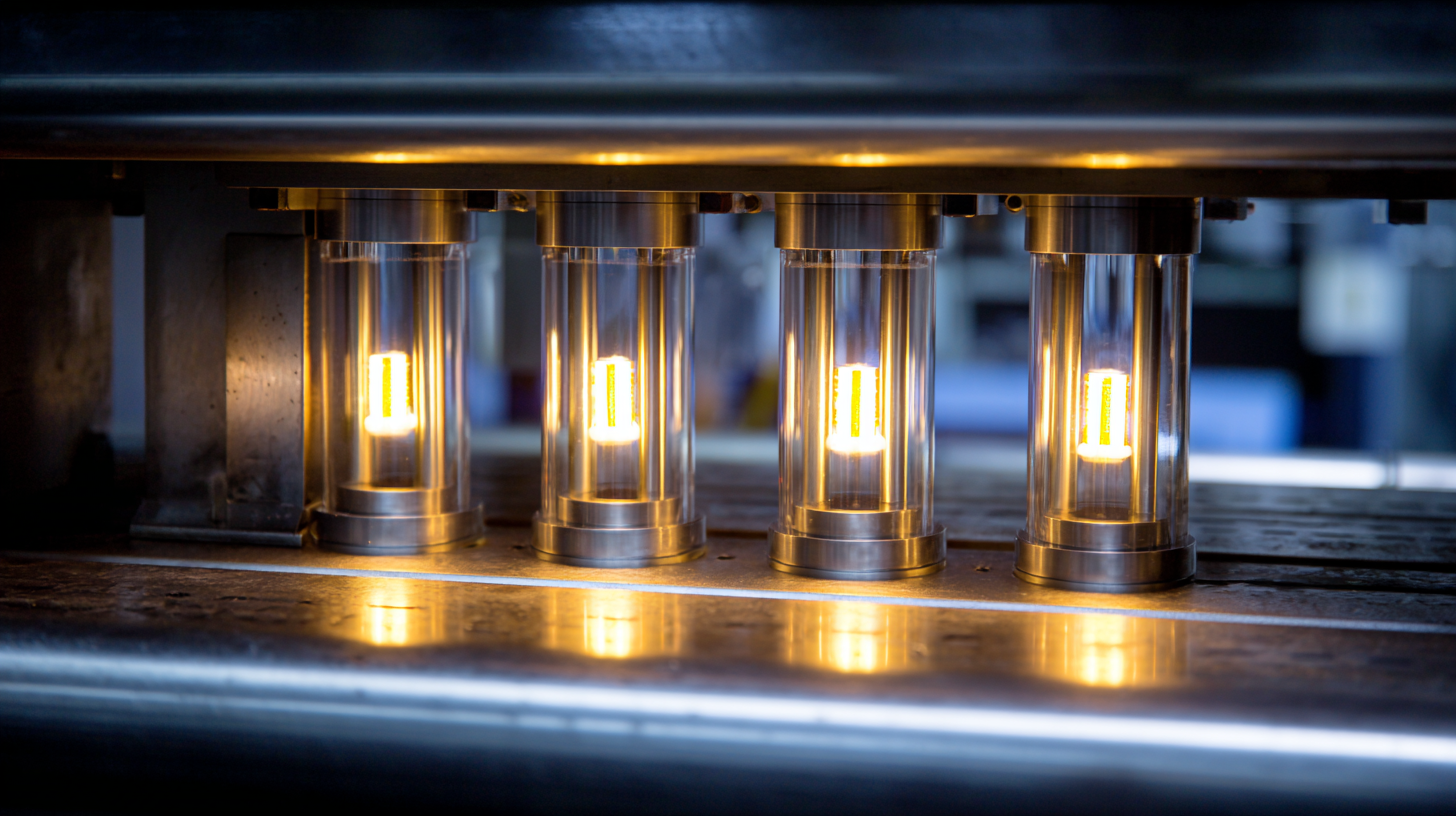

Rod heaters, a versatile and efficient thermal solution, play a crucial role in various modern industries, ranging from food processing to chemical manufacturing. According to a report by the Global Industrial Heating Equipment Market, the demand for advanced heating solutions, including rod heaters, is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2025. This trend highlights the increasing reliance on innovative heating technologies to enhance production efficiency and energy management.

Rod heaters, a versatile and efficient thermal solution, play a crucial role in various modern industries, ranging from food processing to chemical manufacturing. According to a report by the Global Industrial Heating Equipment Market, the demand for advanced heating solutions, including rod heaters, is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2025. This trend highlights the increasing reliance on innovative heating technologies to enhance production efficiency and energy management.

Rod heaters, known for their durability and precise heating capabilities, can significantly reduce operational costs and improve product quality. With applications spanning across industries like plastics, pharmaceuticals, and oil and gas, understanding the science behind rod heaters is essential for leveraging their full potential and ensuring compliance with industry standards.

As businesses strive for sustainable practices, the integration of rod heaters becomes not just beneficial but imperative for competitive advantage.

Rod heaters are specialized devices that utilize electrical resistance to generate heat efficiently. The fundamental principle behind their operation lies in Joule's Law, where the electric current passing through a conductor produces heat proportional to the resistance. Rod heaters typically consist of a durable metal casing that encloses a resistive heating element. When electricity flows through this element, it heats up, transferring thermal energy to its surroundings. The design usually features a uniform cross-section to ensure even heat distribution and minimize hotspots, making them ideal for various applications.

In terms of design principles, rod heaters are engineered to provide maximum thermal efficiency and durability. The materials used in their construction, such as stainless steel or aluminum, are selected for their ability to withstand high temperatures and resist corrosion. Additionally, the heaters are often designed with safety features like thermal cutoffs to prevent overheating. These elements make rod heaters suitable for a wide range of industrial applications, from warming fluids in manufacturing processes to providing heat in food preparation. Their versatility and efficiency signify their essential role in modern industrial environments.

Rod heaters are increasingly becoming essential in various modern industries due to their versatility and efficiency in heating applications. In the plastics and rubber industries, rod heaters are crucial for maintaining optimal material temperatures during processing. They ensure consistent melt temperatures, which enhance product quality and reduce defects in items such as molded plastics and rubber components. This controlled heating is vital for achieving precise flow rates and consistent product performance.

In the food processing sector, rod heaters play a significant role in equipment like cooking kettles and heat exchangers. They provide reliable and uniform heat, essential for maintaining quality in products ranging from sauces to chocolates. Similarly, in the chemical and pharmaceutical industries, these heaters are utilized for maintaining reaction temperatures, preventing hazardous solidification, and ensuring uniform mixing. The adaptability of rod heaters for various applications makes them indispensable in modern industrial operations, where efficiency and precision are paramount.

Rod heaters have become increasingly popular in various modern industries due to their exceptional efficiency and energy consumption benefits. According to a report by the U.S. Department of Energy, industrial heating processes account for nearly 30% of the energy usage in manufacturing. Rod heaters offer a significant reduction in energy consumption, with reported efficiencies of up to 95%. This efficiency stems from their ability to provide direct heating to materials, minimizing heat loss and speeding up processing times.

Furthermore, industries utilizing rod heaters can experience a substantial reduction in operational costs. A study published in the Journal of Industrial Heating Technology revealed that companies implementing rod heaters reported up to a 40% decrease in energy costs compared to traditional heating methods. The precise temperature control and quick response times of rod heaters not only enhance productivity but also reduce the carbon footprint of operations, aligning with modern sustainability goals. As industries continue to evolve, the integration of rod heaters presents a compelling case for optimizing energy consumption while maintaining high performance.

When utilizing rod heaters in industrial applications, safety is paramount. These devices, designed to provide efficient heating, can pose risks if not handled correctly. One major consideration is proper installation; ensuring that rod heaters are placed correctly within their designated environment reduces the chance of overheating and potential hazards. Additionally, users should regularly check for any signs of wear or damage that might compromise the heater's integrity, as issues like insulation breakdown can lead to electrical failures or fire risks.

Best practices for rod heater usage also include implementing reliable temperature control systems. By maintaining optimal operating temperatures, industries can prevent overheating situations that may arise from inconsistent heat distribution. It’s equally important to provide adequate training for personnel who interact with these heaters. Understanding the manufacturer's guidelines and safety protocols can minimize the likelihood of accidents. Moreover, integrating safety features such as thermal fuses or circuit breakers can add an extra layer of protection, ensuring that rod heaters operate safely and efficiently in modern industrial settings.

| Application Area | Rod Heater Type | Operating Temperature (°C) | Power Rating (kW) | Safety Considerations |

|---|---|---|---|---|

| Chemical Processing | Immersion Rod Heaters | 150 - 200 | 5 | Ensure proper insulation and secure connections |

| Food Processing | Flanged Rod Heaters | 80 - 120 | 3 | Regular maintenance and cleaning |

| Pharmaceuticals | Cast-in Rod Heaters | 180 - 220 | 7 | Monitor for overheating and overcurrent protection |

| Plastics Manufacturing | Flexible Rod Heaters | 200 - 260 | 10 | Use certified materials and comply with safety regulations |

| HVAC Systems | Duct Rod Heaters | 50 - 100 | 2 | Ensure proper airflow and temperature control |

As industries evolve, rod heater technology is witnessing significant innovations that aim to enhance efficiency and reduce energy consumption. Recent reports indicate that the global market for industrial heating elements, including rod heaters, is projected to reach USD 7.5 billion by 2025, growing at a CAGR of 5.4% from 2020 to 2025. This growth is driven by the increasing demand for precise temperature control in manufacturing processes and the adoption of advanced materials that improve heat distribution and durability.

One of the most noteworthy trends in rod heater technology is the integration of smart sensors and IoT capabilities. According to a study by MarketsandMarkets, the smart heating market is expected to grow from USD 11.5 billion in 2020 to USD 29.6 billion by 2025, highlighting the role of digitalization in modern heating solutions. These innovations allow for real-time monitoring and adjustment of temperature settings, significantly increasing operational efficiency while minimizing energy waste. Furthermore, advancements in materials, such as the use of high-performance alloys and ceramics, are enhancing the lifespan and performance of rod heaters, making them more reliable and cost-effective for various industrial applications.