Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

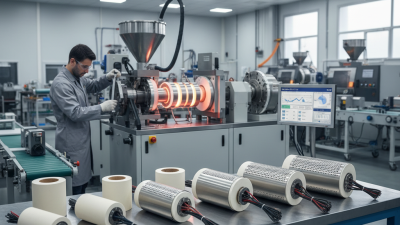

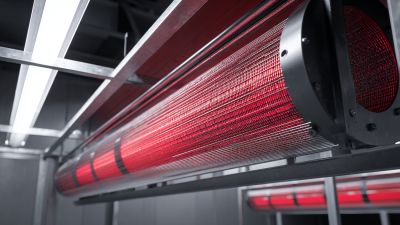

In today’s industrial landscape, efficiency is key. The choice of heating elements can significantly impact operational costs. One innovation that stands out is the Ceramic Band Heater. This technology has gained traction due to its ability to provide uniform heat, saving energy while maintaining optimal performance.

According to industry reports, Ceramic Band Heaters are known for their rapid heat-up times and durability. Their construction allows for effective temperature regulation, reducing wasted energy by up to 30%. This is particularly relevant in sectors like plastics and packaging, where precise temperature control is essential. However, it is worth noting that not all Ceramic Band Heaters are created equal. Quality can vary, leading to inconsistent performance in some cases.

Embracing Ceramic Band Heaters can lead to measurable improvements. Companies using these heaters often report lower maintenance costs and enhanced productivity. Nevertheless, users must regularly assess their heater selections to ensure they meet evolving operational demands. Investing in high-quality Ceramic Band Heaters could lead to long-term benefits, but awareness of potential pitfalls is crucial.

Ceramic band heaters are essential in various industries today. Their performance is rooted in their design. They provide uniform heat distribution. This feature ensures that materials are evenly heated. As a result, productivity increases. Workers spend less time managing heating issues.

Efficiency is another significant aspect. Ceramic materials can withstand high temperatures. They consume less energy than traditional heaters. Over time, this saves money on energy bills. Moreover, these heaters have a faster heat-up time. This means quicker processing cycles. However, users must be mindful of potential overheating. Effective monitoring is needed to prevent damage.

Additionally, ceramic band heaters can be customized. They can fit different machine configurations. Yet, the installation requires careful planning. If improperly installed, they may not function as intended. Understanding the heating requirements of specific applications is crucial. A lack of attention here can lead to inefficiencies.

Ceramic band heaters are gaining traction in various industrial applications due to their enhanced energy efficiency. Reports indicate that these heaters can reduce power consumption by up to 30% when compared to traditional heating methods. This reduction translates into significant cost savings for manufacturers. With rising energy prices, reducing power use is critical.

In some cases, ceramic band heaters provide uniform heat distribution. This feature minimizes temperature variation, which is vital for processes dependent on precision. For instance, industries that require constant heating, like plastics or packaging, benefit immensely. The ability to maintain specific temperature levels reduces waste and improves overall productivity.

However, not all applications may find ceramic band heaters suitable. Some users report difficulties in installation and compatibility with existing systems. Additionally, the initial investment can be higher than conventional heaters. It's essential for companies to evaluate their specific needs and consider the long-term benefits of energy savings. Balancing initial costs against operational efficiency is crucial for effective decision-making.

| Benefit | Description | Impact on Energy Efficiency |

|---|---|---|

| Enhanced Thermal Conductivity | Ceramic band heaters provide superior heat transfer to the targeted area, ensuring efficient heating. | Reduces energy loss and improves overall efficiency. |

| Rapid Heating | Faster heating times lead to shorter production cycles and reduced energy consumption. | Minimizes power usage during idle periods. |

| Lower Energy Costs | Reduced power consumption translates to significant cost savings on energy bills. | Improves bottom line with decreased operational costs. |

| Sustained Performance | Stable temperature profiles contribute to improved process control. | Enhances process efficiency and product quality. |

| Durability and Longevity | Ceramic materials withstand high temperatures and reduce maintenance costs. | Longer heater life results in lower energy waste over time. |

| Versatile Applications | Suitable for various industrial processes, adding to their utility in multiple settings. | Facilitates more effective and efficient energy usage across different applications. |

| Reduced Emissions | Lower energy consumption leads to decreased greenhouse gas emissions during operation. | Supports sustainability initiatives in manufacturing. |

| Improved Worker Safety | Lower operational temperatures decrease the risk of burns and accidents. | Promotes a safer work environment while maintaining energy efficiency. |

| Ease of Installation | Simple setup process minimizes downtime and enhances productivity. | Contributes to swift energy savings during installation phases. |

| Customizability | Heaters can be tailored to specific applications, ensuring optimal performance. | Maximizes energy utilization across diverse heating needs. |

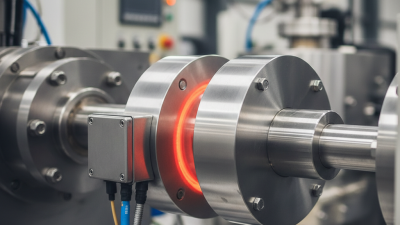

Ceramic band heaters showcase impressive rapid heating capabilities, significantly outpacing traditional heating solutions. Their efficient design allows for quick heat transfer, ensuring that machines reach optimal temperatures faster. This is crucial in industrial settings where downtime can lead to significant loss.

Tips: Always monitor temperature closely during operation. This helps prevent overheating. Adjust settings carefully based on material specifications.

Another noteworthy detail is their energy efficiency. Ceramic band heaters consume less energy compared to traditional options. This efficiency translates into lower operating costs. However, users must be aware of the initial setup complexities. Installation may require professional assistance, which can be a hurdle.

Tips: Consider energy audits regularly. They can reveal savings opportunities. If you're unsure about setup, consult experienced technicians.

Overall, ceramic band heaters are a robust solution for heating applications. Their rapid heating capabilities can enhance productivity, but operators must adapt to new technologies for the best results.

Ceramic band heaters are renowned for their impressive lifespan and durability. These heaters are designed to endure harsh industrial environments. They can withstand high temperatures without losing efficiency. Many facilities report that ceramic heaters last significantly longer than traditional options. This extended lifespan translates to fewer replacements and reduced downtime.

However, not all ceramic heaters are created equal. It's essential to understand the quality standards of your chosen heater. Longevity metrics can vary widely. Some may claim long-lasting performance but fall short in real-world applications. Thorough testing and certifications ensure that a heater meets industry standards. Regular inspections can help identify any wear or damage early.

Choosing ceramic band heaters is a wise investment. Yet, overlooking maintenance can lead to unexpected failure. It's crucial to monitor performance periodically and replace components as needed. This proactive approach helps maintain efficiency and safety. With careful attention, ceramic heaters can provide a remarkable return on investment.

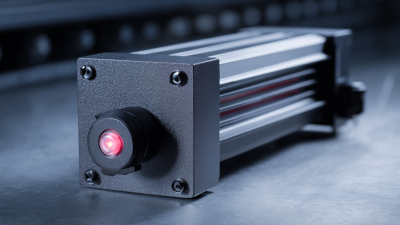

In high-temperature environments, safety is paramount. Ceramic band heaters excel in providing that critical safety layer. They often come equipped with reliable insulation to minimize heat loss. This feature prevents accidental burns. Users feel more secure when handling equipment around these heaters.

Another key safety feature is the temperature control. Many ceramic heaters include built-in thermostats. These help maintain a consistent temperature, reducing the risk of overheating. Overheating can lead to equipment damage or even fires. Regular monitoring is essential, as human error can occur. Visual alerts help operators stay informed.

However, challenges still persist. Some heaters may not distribute heat evenly, creating hot spots. This inconsistency requires careful attention. Operators must conduct regular inspections to ensure safety features function correctly. Maintenance is vital to avoid potential hazards. Reflection is necessary to improve safety protocols continually.