Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

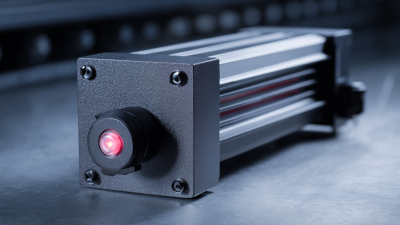

In recent years, the demand for Industrial Infrared Heaters has surged significantly, driven by their efficiency and versatility in various industrial applications. According to a report from Grand View Research, the global infrared heater market is projected to reach $1.5 billion by 2025, growing at a CAGR of 12.5% from 2019. This highlights the increasing reliance on these heating solutions to improve energy consumption and operational productivity across sectors such as manufacturing, automotive, and food processing.

Dr. Emily Thompson, a renowned expert in thermal technology, notes, “Industrial Infrared Heaters play a crucial role in enhancing production efficiency while minimizing energy waste. Their ability to provide targeted heating can lead to significant cost savings for manufacturers.” As industries are under constant pressure to optimize resources and reduce their carbon footprint, infrared heaters are becoming a pivotal technology to consider.

As we delve into the benefits and buying guide for the top Industrial Infrared Heaters of 2025, it’s essential to understand the key features, applications, and advancements in technology that make these systems indispensable in the modern industrial landscape. Emphasizing efficiency, safety, and innovation, this guide will equip you with the insights necessary to make informed investment decisions in this dynamic market.

As industries continue to evolve, the demand for efficient and effective heating solutions is becoming increasingly critical. In 2025, industrial infrared heaters stand out due to their unique characteristics that offer substantial operational benefits. These heaters operate by emitting infrared radiation, which directly heats objects and surfaces, leading to minimized energy loss and maximized thermal efficiency. Reports indicate that industrial infrared heaters can achieve energy efficiency ratings of up to 90%, significantly higher than traditional convection heating methods, which typically hover around 60-70%.

Another key feature of modern infrared heaters is their rapid heating capabilities. Advanced technologies now allow for instant heat generation, accommodating quick production cycles and less downtime during operations. According to a market analysis by industry experts, manufacturers utilizing infrared heaters have reported an average reduction in heating time by 30-50%. Furthermore, the adaptability of these heaters to various industrial environments is noteworthy; they can operate effectively in both ambient and confined spaces, making them suitable for a diverse range of applications such as curing, drying, and pre-heating materials.

Additionally, the integration of smart technology in industrial infrared heaters is transforming operational efficiencies. Features such as programmable controls and real-time monitoring systems enable businesses to achieve precise temperature regulation, further improving energy management. Studies have shown that companies leveraging smart infrared heating solutions can enhance their productivity by up to 25% while simultaneously reducing greenhouse gas emissions, aligning with global sustainability goals.

| Model | Power (kW) | Heating Area (sq. ft.) | Temperature Range (°F) | Efficiency (%) | Weight (lbs) | Price (USD) |

|---|---|---|---|---|---|---|

| Model A | 5 | 400 | 120-180 | 85 | 50 | 750 |

| Model B | 7.5 | 600 | 130-200 | 90 | 60 | 950 |

| Model C | 10 | 800 | 140-220 | 88 | 70 | 1200 |

| Model D | 12 | 1000 | 150-240 | 92 | 80 | 1500 |

Infrared heating technology has gained significant traction in industrial settings due to its unique advantages over conventional heating methods. One of the primary benefits is energy efficiency. Infrared heaters work by directly heating objects and surfaces rather than the air around them, which minimizes heat loss and results in lower energy consumption. This direct heating approach not only enhances operational efficiency but also leads to substantial cost savings in energy bills, making it an attractive option for businesses looking to optimize their heating systems.

Another advantage of infrared heating lies in its rapid response time. Unlike traditional heating systems that can take time to reach desired temperatures, infrared heaters provide instant warmth, allowing for quicker process cycles in various industrial applications. This feature is particularly beneficial in environments where time-sensitive operations are critical, such as curing, drying, and heating processes. Moreover, infrared heating provides uniform heat distribution, reducing the risk of hot or cold spots, which can compromise product quality and consistency. Hence, when incorporating infrared technology, industries can enhance both productivity and precision in their operations.

When considering the purchase of industrial infrared heaters, there are several key factors to take into account to ensure optimal functionality and efficiency. First, it’s essential to evaluate the specific heating needs of your industrial application. Factors such as the size of the area to be heated, the type of materials being processed, and the desired temperature range will significantly influence the type of infrared heater you should select. Assessing these requirements will help you choose a unit that can effectively provide the necessary heat while avoiding energy waste.

Moreover, you should pay attention to the power source of the infrared heater, as this can vary between electric and gas models. Understanding the availability of energy sources in your facility is crucial, as this impacts both operational costs and the ease of installation. Additionally, consider the heater's construction materials and safety features, as durable materials can extend the lifespan of the equipment, minimizing maintenance costs. Finally, examining the heater's efficiency ratings will help you determine its performance, ensuring that your investment will deliver the required heat transfer while being cost-effective in the long run.

When selecting infrared heaters for industrial applications, it's essential to consider a variety of brands and models that cater to specific needs. Top brands often differentiate themselves by focusing on efficiency, durability, and performance in harsh environments. Industrial infrared heaters are designed to deliver rapid heating while minimizing energy consumption, making them an excellent choice for large spaces where traditional heating methods may fall short.

Several popular models feature advanced technologies such as shortwave, medium-wave, and long-wave infrared heating elements, each suited for different tasks and settings. Shortwave heaters, for instance, are ideal for quick heating in outdoor areas, while medium and long-wave models excel in applications requiring gentle, sustained warmth. The choice of model should also take into account the intended use—whether for drying, curing, or maintaining temperature, ensuring optimal heat distribution to enhance operational efficiency.

To ensure optimal performance of industrial infrared heaters, regular maintenance is essential. One key aspect is keeping the heating elements and surrounding surfaces free of dust and debris, which can impede heat transfer and efficiency. Periodically inspecting connections and wiring for wear or damage helps prevent potential safety hazards and ensures reliable operation. Additionally, checking the reflector's condition and cleaning it can enhance performance by increasing the intensity of the infrared radiation directed toward the intended area.

Safety tips are equally crucial when operating infrared heaters. Always ensure that heaters are situated away from flammable materials and that they have adequate ventilation. It’s advisable to use heaters equipped with safety features such as automatic shut-off mechanisms to mitigate overheating. Operators should familiarize themselves with the heater's operating instructions to ensure proper use. Finally, regular training on safety protocols can help prevent accidents and ensure that all personnel are aware of the necessary precautions for safe operation.