Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

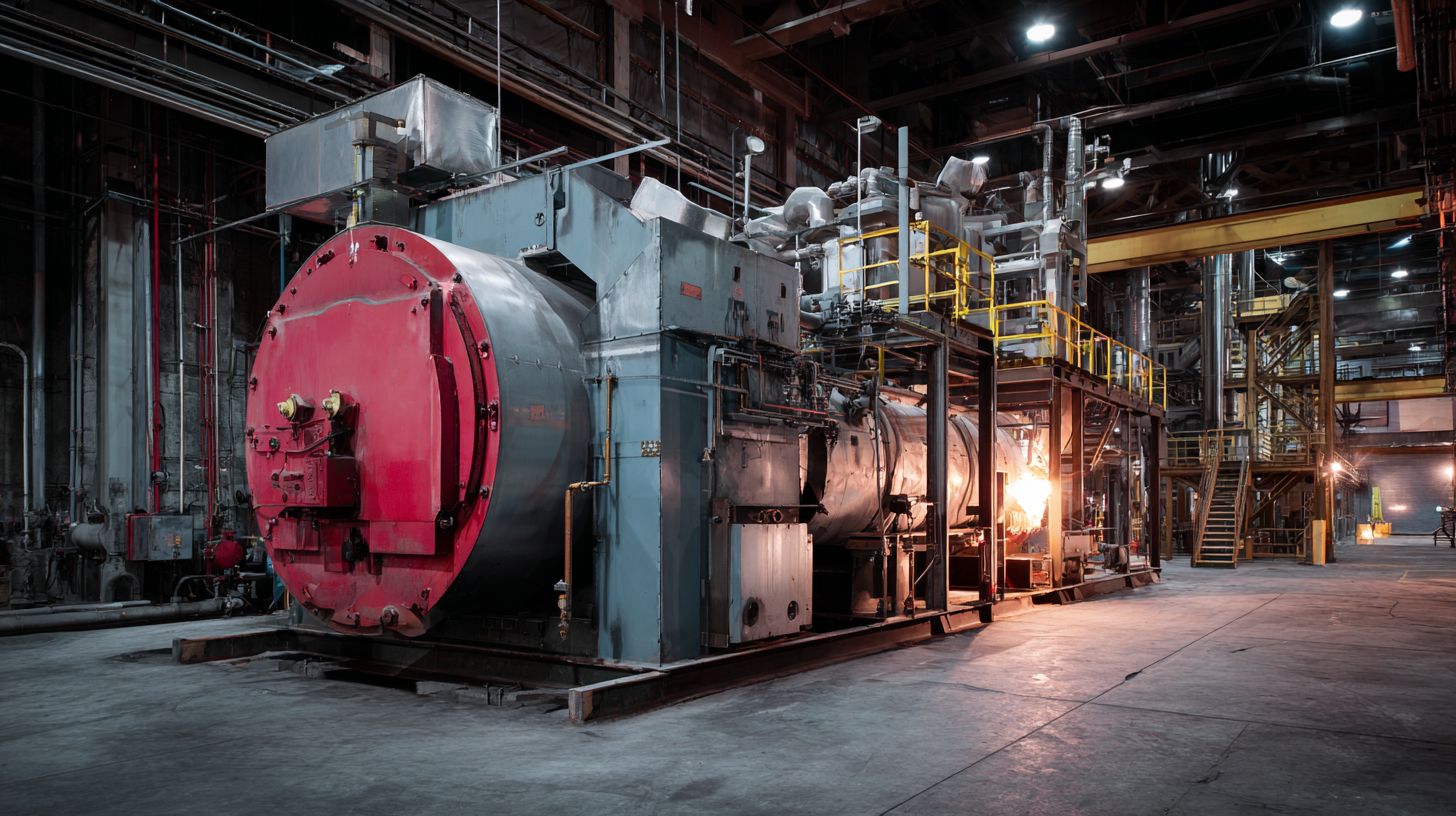

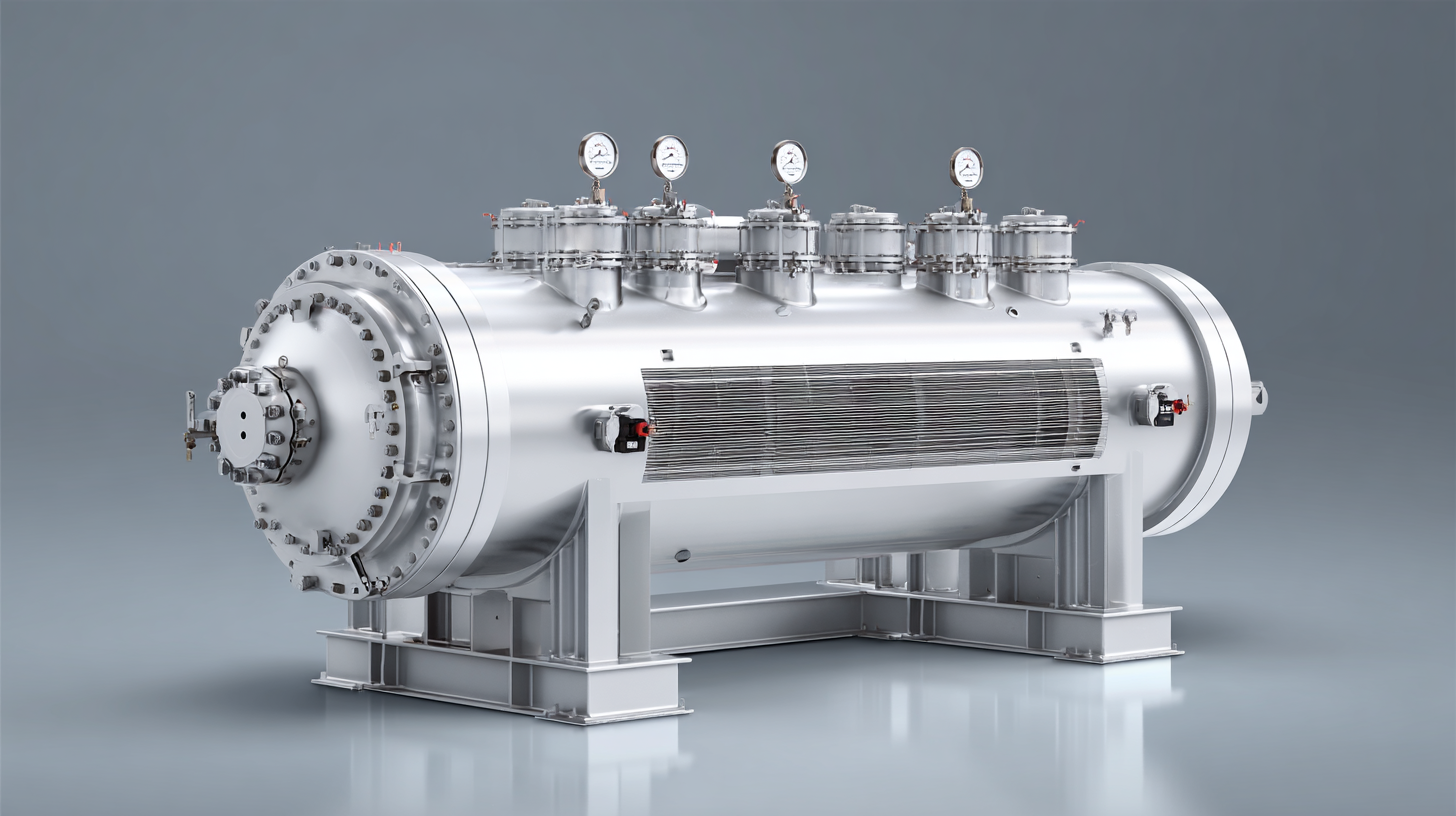

In today's industrial landscape, the pursuit of energy efficiency is more critical than ever, especially as energy costs continue to rise. A recent report by the U.S. Department of Energy highlights that industrial facilities account for nearly 30% of total U.S. energy consumption, making it imperative for industries to adopt innovative technologies. One such technology, the Radiant Process Heater, has emerged as a game changer for various industrial applications. By utilizing infrared radiation to directly heat materials, these heaters can reduce energy costs by up to 30%, significantly impacting operational expenses. Moreover, the Thermal Efficiency and Heat Transfer Assessment conducted by the International Energy Agency indicates that integrating Radiant Process Heaters not only lowers energy consumption but also improves production consistency and product quality. As industries strive to enhance their sustainability profiles, Radiant Process Heaters present a compelling solution to unlock efficiency and drive economic performance in energy-intensive processes.

Radiant process heaters are emerging as a pivotal solution for industrial settings looking to enhance efficiency while minimizing energy costs. These systems transfer heat through radiation, which allows for more uniform heating and reduced energy waste compared to traditional heating methods. As industries face mounting pressure to curb fuel consumption and lower CO2 emissions, radiant heaters offer a compelling advantage by operating at higher efficiencies. This efficiency can lead to a remarkable reduction in energy costs by as much as 30%, making them an attractive alternative for processing facilities.

Moreover, the shift towards radiant process heaters aligns with the broader industry goals of sustainability. By optimizing fuel combustion and focusing on advanced heating technologies, these systems can significantly decrease carbon footprints, contributing to the fight against climate change. Incorporating radiant heaters into industrial applications not only supports stricter environmental regulations but also positions companies as leaders in eco-friendly practices. As such, the advantages of radiant process heaters are multifaceted, enhancing operational efficiency while promoting responsible energy use.

| Dimension | Metric | Value |

|---|---|---|

| Energy Cost Reduction | Percentage | 30% |

| Efficiency Improvement | Percentage | 25% |

| Average Lifespan | Years | 15 |

| Installation Time | Days | 5 |

| Reduction in Emissions | Percentage | 20% |

| Payback Period | Months | 24 |

In industrial applications, optimizing energy use through radiant heating technology presents a significant opportunity to reduce costs and enhance efficiency. Radiant process heaters operate by efficiently transferring heat directly to the surface of materials, minimizing energy loss and improving thermal comfort. By adopting this technology, industries can achieve noteworthy reductions in energy consumption—potentially cutting costs by as much as 30%. This novel approach not only streamlines operations but also contributes to sustainability efforts by lowering overall energy demands.

In industrial applications, optimizing energy use through radiant heating technology presents a significant opportunity to reduce costs and enhance efficiency. Radiant process heaters operate by efficiently transferring heat directly to the surface of materials, minimizing energy loss and improving thermal comfort. By adopting this technology, industries can achieve noteworthy reductions in energy consumption—potentially cutting costs by as much as 30%. This novel approach not only streamlines operations but also contributes to sustainability efforts by lowering overall energy demands.

Recent advancements in thermal management, akin to those seen in electric vehicle infrared heating systems, illustrate the value of efficient thermal control in enhancing performance. The MINDED research project aims to innovate thermal management systems that could similarly enhance energy efficiency in various applications. As industries continue to seek ways to optimize energy use, the integration of radiant heating technology alongside innovative thermal management strategies will be crucial in achieving both economic and environmental objectives. Emphasizing the synergy between these technologies can create a pathway for sustainable industrial growth.

In recent years, industrial applications have increasingly adopted radiant process heaters to enhance energy efficiency and reduce operational costs. A notable case study from a manufacturing facility highlights how the implementation of these heaters led to a remarkable 30% reduction in energy expenses. By directly heating the target materials instead of relying on ambient air, they minimized heat loss and improved thermal efficiency. This innovative approach not only cut costs but also streamlined the production process, resulting in faster turnaround times.

Another example can be seen in the food processing sector, where a company upgraded its heating systems to incorporate radiant technology. This transition resulted in significant energy savings by optimizing the heating cycle and reducing the time required to achieve desired temperatures. The case demonstrated that integrating radiant process heaters not only lessens energy consumption but also enhances product quality. The combination of lower costs and better quality has solidified the role of radiant heaters as a pivotal component in modern industrial practices, promising more sustainable and profitable operations.

In industrial applications, the choice of heating method can significantly impact energy efficiency and operational costs. Radiant process heaters offer a distinct advantage over traditional heating methods such as convection and resistance heaters. Unlike conventional systems that heat the air and rely on convection to warm surfaces, radiant heaters emit infrared radiation that directly heats objects and surfaces. This results in faster heating times and reduced energy waste, leading to a potential energy cost reduction of up to 30%.

When comparing radiant process heaters with traditional methods, it's crucial to consider factors such as installation cost, maintenance, and flexibility. Radiant heaters often have a higher initial investment but provide quick returns through decreased energy consumption. Additionally, their ability to focus heat on specific areas minimizes energy loss, which is a common issue with standard heating systems.

Tips: To maximize the efficiency of radiant process heaters, consider optimizing your facility layout to ensure that heat is applied where it is most needed. Regular maintenance checks can also help maintain peak performance, ensuring that your heating system operates effectively and minimizes downtime. Moreover, training staff on how to operate these systems can lead to further improvements in energy management.

The industrial landscape is witnessing a transformative shift towards smart manufacturing and enhanced energy efficiency as companies aim to reduce operational costs and environmental impact.

Radiant process heaters are emerging as a pivotal technology in this context, enabling industries to cut energy expenses by up to 30%. This remarkable efficiency aligns with global trends emphasizing sustainability and the adoption of advanced heating solutions that optimize processes while minimizing waste.

Radiant process heaters are emerging as a pivotal technology in this context, enabling industries to cut energy expenses by up to 30%. This remarkable efficiency aligns with global trends emphasizing sustainability and the adoption of advanced heating solutions that optimize processes while minimizing waste.

In the broader framework of industrial energy efficiency, market forecasts indicate significant growth within the renewable energy sector, expected to reach $1,020.94 billion in 2024. This trajectory highlights the increasing investment and interest in green technologies that not only meet regulatory demands but also cater to the rising ecological consciousness among consumers.

Industries are now more inclined to integrate cutting-edge solutions like radiant heating systems, which can significantly improve their energy profiles, thereby remaining competitive in a rapidly evolving market demanding innovation and sustainability.